16

Aug

How to Choose the Right 12V DC Motor for Your Project?

Selecting the right 12V DC motor for your project requires a systematic evaluation of technical specifications and operational needs. The goal is to match the motor’s performance to your application’s mechanical demands, ensuring efficiency, reliability, and cost-effectiveness. Below is a step-by-step guide to the key selection criteria.

1. Define Torque Requirements

Torque is the rotational force a motor must generate to drive a load—such as lifting, pushing, or rotating components.

- Starting torque: Ensure the motor can overcome static friction and initiate motion. For high-inertia loads (e.g., heavy gears or flywheels), select a motor with a starting torque 1.5 to 2 times the rated operating torque.

- Continuous torque: Match the motor’s rated continuous torque to the steady-state load. Operating above this value leads to overheating and reduced lifespan.

Example: A small conveyor belt requiring 0.5 N·m of continuous torque should use a 12V motor rated for at least 0.5 N·m at 12V under full load.

2. Determine Speed Needs

Speed, measured in revolutions per minute (RPM), determines how fast the load operates. It must align with the functional requirements of your system.

- Fixed speed: For applications like fans or pumps, choose a motor with a rated speed that matches the desired output (e.g., 3000 RPM for a cooling fan).

- Variable speed: If adjustable speed is required (e.g., in robotics or precision tools), select a motor compatible with PWM (pulse-width modulation) controllers, ensuring smooth and stable control across the target range (e.g., 500–3000 RPM).

3. Choose Between Brushed and Brushless Motors

12V DC motors are primarily available in two types, each with distinct trade-offs:

- Brushed motors: Lower cost and simpler wiring make them ideal for low-duty-cycle or budget-sensitive projects (e.g., DIY toys, small actuators). However, they have a shorter lifespan due to brush wear and lower efficiency—typically 60–70%.

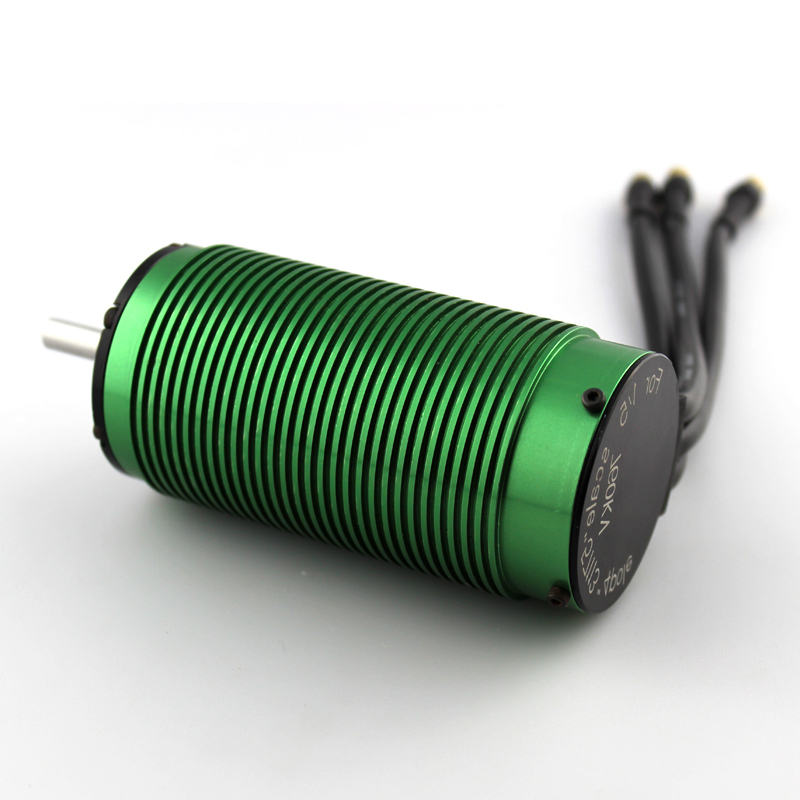

- Brushless motors (BLDC): Offer higher efficiency (80–90%), longer service life (no mechanical brushes), and better performance in continuous or high-precision applications (e.g., automated systems, medical devices). They require an electronic speed controller (ESC), which increases initial cost and complexity.

4. Evaluate Physical Constraints

Size and weight are critical in space-limited designs.

- Compact motors (e.g., N20 or 37mm diameter) are suitable for small devices like drones or handheld tools.

- Larger motors (e.g., 55mm diameter or more) are better for heavy-duty applications such as electric carts or industrial actuators.

Also, verify mounting options—such as threaded holes, flanges, or brackets—to ensure secure integration with gearboxes, shafts, or structural components.

5. Consider Environmental Conditions

Operating environment significantly affects motor longevity and performance.

- Temperature range: Standard motors operate between -20°C and +60°C, which is sufficient for most indoor applications. For extreme environments (e.g., outdoor or industrial settings), select motors rated for wider temperature ranges.

- Ingress protection (IP rating): In dusty or damp conditions, use motors with appropriate IP ratings. For example, IP54 provides protection against dust and water splashes.

6. Verify Power Supply Compatibility

Ensure the motor’s current draw at 12V is within the capacity of your power source.

- Estimate current using the formula:

I = P / V,

where power (P) in watts equals (torque × speed) ÷ 9.55.

For example, a 12V motor delivering 12W of mechanical power draws approximately 1A. - Always use a power supply or battery (e.g., 12V 2A) with a current rating higher than the motor’s peak demand to prevent voltage sag, overheating, or brownouts.

Summary

Choosing the right 12V DC motor involves balancing torque, speed, motor type, physical size, environmental resilience, and power compatibility. Use brushed motors for simple, low-cost, intermittent-use applications. Opt for brushless motors when you need high efficiency, long life, and precise control in continuous-operation systems. Always validate your selection with real-world load testing to ensure reliable and optimal performance.

hat concludes our introduction to “How to Choose the Right 12V DC Motor for Your Project?”. If you have any requirements for purchasing motors, please visit our online store. 3650 brushless motor