18

Aug

What Is a Coreless DC Motor?

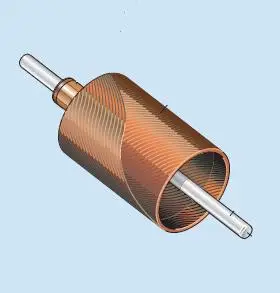

A coreless DC motor is a specialized type of direct current motor that eliminates the traditional iron core from its armature winding. Instead, the coil is formed into a self-supporting hollow cylinder—often referred to as an “air-core” design—eliminating magnetic saturation and significantly reducing rotational inertia. These characteristics distinguish coreless motors from conventional iron-cored DC motors.

Structural Features

Coreless Armature:

The armature consists of a lightweight winding made from copper or aluminum, shaped into a cylindrical or disk-like structure without an iron core. This design reduces magnetic hysteresis and eddy current losses, while also minimizing the motor’s overall mass.

Permanent Magnet Stator:

The stator typically uses high-strength rare-earth magnets—such as neodymium-iron-boron (NdFeB)—arranged radially to generate a uniform magnetic field that interacts with the current-carrying armature coil.

Commutation System:

Brushed coreless motors use a mechanical commutator and carbon brushes to reverse current direction in the armature. Brushless variants (BLDC coreless motors) rely on electronic controllers for precise, sensor-based or sensorless commutation.

Operational Principles

Like all DC motors, coreless motors operate on the principle of electromagnetic force: when current flows through the armature coil, it interacts with the stator’s magnetic field, producing torque that drives rotation. Because there is no iron core, coreless designs avoid eddy current losses and hysteresis losses, resulting in higher efficiency—especially at low speeds and during rapid start-stop cycles.

Key Advantages

- High Efficiency:

The absence of an iron core eliminates core losses, enabling efficiency levels of 85–95%, significantly higher than most cored DC motors (typically 70–85%). - Low Rotor Inertia:

The lightweight armature allows for extremely fast acceleration and deceleration, making these motors ideal for applications requiring high dynamic response—such as robotics, camera autofocus systems, and precision positioning. - Smooth Operation:

Without the iron teeth found in cored motors, coreless designs eliminate cogging torque (torque ripple caused by magnetic attraction between core and stator), delivering near-sinusoidal torque output and vibration-free motion. - Compact and Lightweight:

Removing the bulky iron core enables significant miniaturization, making coreless motors suitable for space-constrained applications like medical devices and portable electronics.

Limitations

- Lower Torque Density:

Due to fewer conductive turns and reduced magnetic flux path efficiency, coreless motors produce less torque per unit volume compared to cored designs, limiting their use in high-torque applications. - Higher Manufacturing Cost:

The precision required to fabricate self-supporting coils and align high-performance magnets increases production complexity and cost. - Thermal Sensitivity:

The lack of an iron core—which normally acts as a thermal mass and heat sink—makes coreless motors more prone to overheating under sustained loads. Thermal management (e.g., forced air, duty cycle control) is often necessary.

Typical Applications

Coreless DC motors excel in applications where speed, precision, compactness, and responsiveness are prioritized over raw torque:

- Medical Devices: Insulin pumps, surgical tools, lab automation.

- Robotics: Micro-actuators, grippers, joint control in small robots.

- Consumer Electronics: Autofocus mechanisms in smartphone cameras, micro-vibration motors, portable cooling fans.

- Aerospace and Defense: Miniaturized sensors, UAV subsystems, guidance actuators.

Summary

A coreless DC motor is a high-performance, lightweight motor optimized for efficiency, dynamic response, and smooth operation. By eliminating the iron core in the armature, it achieves faster response times and higher efficiency than traditional cored motors—particularly in low-inertia, precision-driven applications. While limited by lower torque density and higher cost, its advantages make it the preferred choice in advanced medical, robotic, and consumer technologies.

hat concludes our introduction to “What Is a Coreless DC Motor?”. If you have any requirements for purchasing motors, please visit our online store. 3650 brushless motor